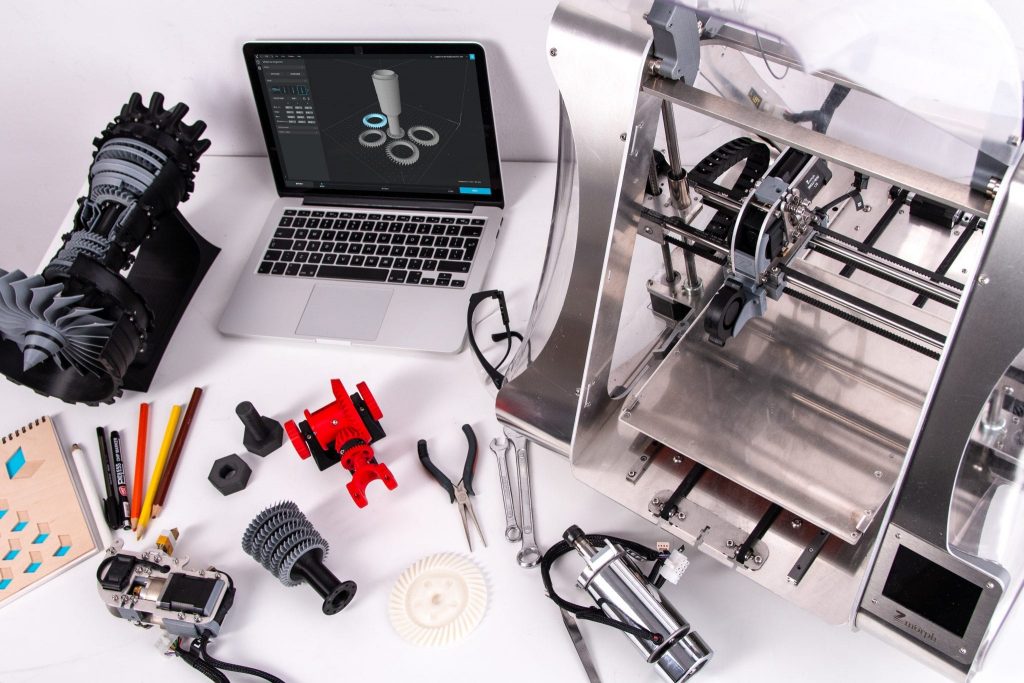

Most 3D printers cannot 3D print large life-size model objects in one step. The same problem applies to objects that you want to scale up yourself. Products that are too large simply do not fit inside a standard 3D printer camera.

How you can do it?

The most obvious way for those who often print large objects is to buy a high-tech 3D printer with a maximum build area. CreatBot D600 Pro is a good example. With a 600x600x600mm print volume, heated bed, and high nozzle temperature, it prints large items with the best quality possible.

For those who are not yet considering purchasing such a device, the methods described below will help to get full-size products regardless of the volume of the device’s camera.

3D printing of large objects

If you’re making the most of your axes, know that large-scale projects are easy to accomplish with a standard desktop 3D printer. For this, there are functions for splitting and slicing 3D models. You can edit objects directly in your 3D modeling software.

Search on the Internet

First of all, try to search for the already divided model in the public domain. Many architects, engineers, and designers upload “sliced” versions online because they know that not all 3D printers are designed to print large items. As a rule, the models divided into parts are an archive of several SLT files. Each can easily fit into a medium-sized cell. Searching the internet is a good way to save time 3D printing large objects.

Splitting multipart SLT files

There is a program like Slic3r that converts a 3D model to G-code and generates detailed instructions for the printer. If the model consists of several simple elements, the application will allow you to work with each of them separately. All parts and layers of the object are configured in a special menu. The user can remove sharp corners, remove or add elements, resize them and even combine several projects into one by placing objects side by side on the board or overlapping them.

Another tool for splitting multicomponent STL files is Autodesk Meshmixer. Here, for convenient work with the STL file, you just need to use the “Split shells” command.

3D Printing Large Objects: Splitting Mesh Along Planes

This feature is available in many CAD systems. For this, the Autodesk Meshmixer program mentioned above is suitable. Import the STL file and click the Edit button. It will allow you to adjust the cutting plane by moving the arrows along the axes. You can also create the plane from which you want to cut the model by drawing the intended cut line.

As for the Slic3r tool, here the cut option only works parallel to the XY plane. However, there is another program – Windows 3D Builder. Click on the “Edit” button and select the split option to see the cut plane. You can rotate the cutting plane at any angle along the three axes and move to the desired position. Besides, precise cutting is possible. The rotation and movement tools can be adjusted in degrees and millimeters, respectively.

Additional tips for bonding elements

Making the above manipulations, make sure that the seams will not be too noticeable when you assemble the product in parts. Use high-quality glue to combine the elements into one structure, because the strength of the object depends on this. Remember that most CAD systems allow you to make adjustments to the design concept. For example, you can make several 2mm holes in pre-selected locations and then insert filaments into them. This will help ease the assembly of the product if you are making any props or functional parts. You can also use metal rods, screws, or bolts for a strong bond.

When you take the model apart, print it, and reassemble it, it is important to pay sufficient attention to the processing of the product. It must be carefully sanded to remove any glue residue that may remain at the joints. Also, grinding can smooth out small misalignments between parts.

If there are gaps between the glued parts, you can use the 3D pen and remove the defects using the melted thread. If you want to paint the model, use putty, various fillers, and other materials.

Picture Credit: Unsplash